Tel: +86-532-84673097

Mobile & Whatsapp & Wechat:+86-13589340409

Mobile & Whatsapp & Wechat:+86-13589340409

| Conveyor Belt Type | Key Features | Suitable Materials | Recommended Conveying Method |

| EP Fabric Conveyor Belt | High strength, impact-resistant, flexible | Limestone, Sand, Gravel | Horizontal, Short Distance |

| NN Conveyor Belt | High flexibility, impact-resistant | Clinker, Sand, Gravel | Horizontal, Short Distance |

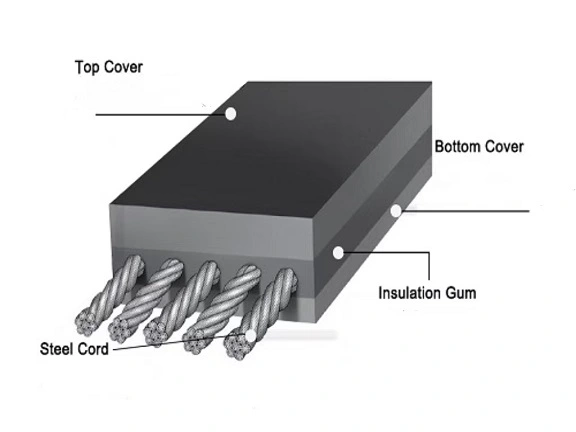

| Steel Cord Conveyor Belt | High strength, suitable for long-distance transport | Long-distance Limestone, Ore | Long-Distance Conveying |

| Anti Tear Steel Cord Conveyor Belt | Prevents tearing from heavy material drops | Mining, Construction Sites | Heavy-Duty & Long-Distance Transport |

| Fire Resistant Steel Cord Conveyor Belt | Flame retardant, suitable for high-temperature environments | Coal, Cement Plants | Long-Distance Transport |

| Heat Resistant Conveyor Belt | Designed for high-temperature clinker transport | Clinker (≤170°C) | Horizontal & Inclined Conveying |

| Fire Resistant Conveyor Belt | Flame-resistant for fire safety compliance | Coal, Cement Industry | Horizontal Transport |

| Oil Resistant Conveyor Belt | Resistant to oil penetration, ideal for oil-containing materials | Oil-Containing Limestone, Coke | Horizontal Transport |

| Acid and Alkali Resistant Conveyor Belt | Suitable for corrosive environments | Chemical Materials, Cement Powder | Horizontal Transport |

| Bucket Elevator Conveyor Belt | Designed for vertical material lifting | Cement Powder, Clinker (≤170°C) | Vertical Transport |

| Steep Angle Conveyor Belt | Suitable for steep incline transport | Clinker, Limestone | Space-Saving, Efficient Transport |

When selecting a construction conveyor belt or conveyor belt used in cement industry, you should consider the following factors:

1. Material Type

The first step in selecting the right conveyor belt is understanding the type of material you’ll be transporting. Different materials have unique characteristics, such as temperature, weight, and abrasiveness, that influence the choice of the belt.

2. Environmental Conditions

Temperature, potential for exposure to chemicals, and the risk of fire or oil exposure all play a part in selecting the right material.

3. Distance and Inclination

The distance and incline of your conveyor system will significantly affect the choice of conveyor belt.

For long-distance transport, steel cord conveyor belts offer the strength and durability to handle heavy loads over long stretches.

If the material needs to be transported vertically or on a steep incline, bucket elevator conveyor belts or steep angle sidewall conveyor belts will maximize space and ensure efficient operation.

4. Load Capacity and Durability

The load the belt needs to carry directly impacts the choice of material and strength. Consider the weight, abrasiveness, and potential for punctures or tears.

The flexible design of Rentone conveyor belts makes them ideal for narrow or hard-to-reach areas. Its adaptable design ensures smooth and reliable material transportation throughout the construction site.

Depending on the needs of the project, Rentone offers customized conveyor belt solutions that meet the specific requirements of the construction industry for material handling, ensuring the safe and efficient transport of all types of materials.

In the world of construction, Rentone Belt stands out as a leading and innovative conveyor belt manufacturer in China. Our diverse product range is meticulously crafted to meet the unique demands of the construction industry.

Featuring high tensile strength and low elongation, it is ideal for heavy-duty, long-span applications in construction sites and cement plants, where materials like cement clinker and ores need to be transported.

Designed for high-temperature environments, it is widely used in cement production, brick manufacturing, and other processes that involve transporting hot materials like clinker and heated sand.

Ideal for handling chemically treated or corrosive materials such as lime and cement additives, ensuring durability in harsh environments.

EP conveyor belts have high strength, high abrasion resistance, good impact resistance and tensile resistance, and can stably convey common construction materials such as sand, limestone, etc.

With high strength, impact resistance, and good flexibility, it is suitable for long-distance transportation of materials such as sand, gravel, and concrete in construction projects.

Suitable for tunnel construction, underground projects, and other fire-prone environments, ensuring safe material transportation by minimizing fire hazards.

Used in asphalt mixing plants or applications involving oil-based additives, preventing rubber degradation and maintaining stable conveyor performance.

Suitable for vertical or steep-angle transportation of powdery or small granular materials like cement powder, sand, and lime, improving efficiency in material handling.

Designed for space-constrained construction sites that require steep-angle conveying, such as aggregate yards and cement plants, allowing efficient transportation with minimal footprint.