Tel: +86-532-84673097

Mobile & Whatsapp & Wechat:+86-13589340409

Mobile & Whatsapp & Wechat:+86-13589340409

| Consideration | Details |

| Material Characteristics | The type of material being conveyed (e.g., sharp, hot, or corrosive) determines the necessary belt material and design. |

| Load Weight and Volume | Choose a conveyor belt with the proper load capacity based on the weight and volume of the materials. The belt must withstand the highest load without failure or excessive wear. |

| Transport Distance and Incline | To avoid material spillage across long distances or steep inclines, employ specialized belts such as sidewall conveyor belts. |

| Environmental Conditions | Temperature, humidity, and chemical exposure all have an impact on belt performance and should influence material and design choices. |

| Conveyor Belt Speed | The belt's speed influences material handling as well as the material and construction of the belt. |

| Belt Size and Width | Proper size promotes effective material handling while preventing overflow or spillage. |

| Maintenance and Repairs | Ease of maintenance and repair is crucial, especially in remote or hostile areas where downtime is expensive. |

| Safety Compliance | Ensure that the belt fulfills industry-specific safety requirements and regulations, particularly in hazardous areas. |

| Cost | Consider not only the initial price, but also the whole cost of ownership, which includes maintenance, downtime, and replacement costs. |

Conveyor belts play a crucial role in the mining industry, facilitating the transportation of various materials and ores from one location to another. Here are some key applications of conveyor belts in the mining industry:

Ore Transportation: Conveyor belts in mining industry are extensively used to transport mined ores from the mining site to the processing plants or stockpiles. These belts can handle heavy loads and are designed to withstand the harsh conditions of mining environments, including dust, abrasion, and high temperatures.

Coal Handling: Conveyor belts are widely used in coal mining operations to transport coal from the extraction point to processing plants or storage areas. These belts are designed to handle large volumes of coal efficiently and safely, ensuring a continuous flow of coal for further processing or shipment.

Overburden Removal: In open-pit mining, conveyor belts are utilized to remove overburden, which refers to the soil, rock, or other materials covering the desired mineral deposits. The overburden is transported away from the mining area using conveyor belts, allowing access to the underlying mineral resources.

Material Sorting and Processing: Conveyor belts are employed in mining operations for sorting and processing various materials. They can be used to separate different grades of ores or minerals based on their size, density, or other characteristics. Conveyor belts also facilitate the transportation of processed materials to the designated storage or loading areas.

Underground Mining: In underground mining operations, conveyor belts are used to transport materials and equipment to and from the mining site.

Open pit and surface mines

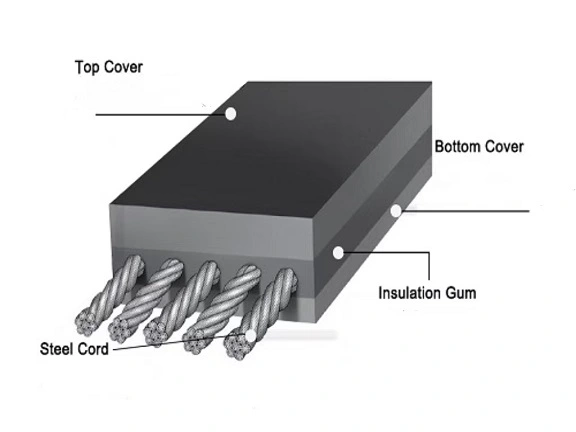

Rentone offers conveyor belt solutions that are suited to the configuration of the conveyor installation and the material to be transported, taking into account factors such as capacity, length, material and block size. For example, our steel cord conveyor belts offer high strength and abrasion resistance to ensure cost-effective transportation of mined material.

Underground mines

For underground mines, with their space constraints and risk of flammable gases, Rentone offers fire resistant conveyor belt solutions with flame-retardant materials to extend belt life and reduce the need for frequent replacements.

Tunneling

Rentone offers highly efficient conveyor belts for tunnel construction, designed for tight spaces to transport heavy loads and construction materials. Our high-temperature and anti tear steel cord conveyor belts ensure long-term stability at high temperatures and high loads.

In the heart of China's industrial prowess, Rentone Belt emerges as a trailblazer in conveyor belt manufacturing. As a leading and innovative conveyor belt manufacturer, we take pride in delivering a diverse range of solutions tailored to the unique needs of industries, including mining. Our product lineup, featuring fabric conveyor belt, steel cord conveyor belt, solid woven conveyor belt, and special conveyor belt, reflects our commitment to excellence. At Rentone, we are not just manufacturers; we are partners in your success, providing conveyor belt solutions that redefine efficiency and reliability in the mining landscape. Trust Rentone Belt – where innovation meets industry.

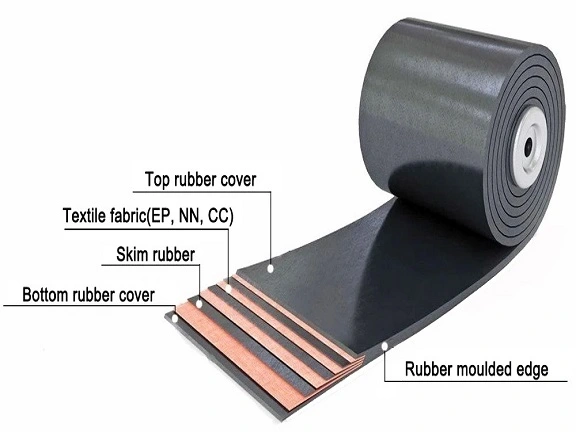

These belts are comprised of numerous layers of fabric separated by rubber, which provide exceptional impact resistance. They're perfect for underground mining operations.

Steel cord belts are strengthened with steel wires to provide great tensile strength, making them ideal for heavy-duty applications. Anti-tear steel cord conveyor belts are specifically engineered to endure high impact and prevent tearing.

These belts are built to resist high temperatures and are used to move commodities like molten ores or hot slag, ensuring dependable performance in high-temperature conditions.

Fire resistant belts, often known as flame-retardant conveyor belts, lower the likelihood of fires in mining operations. They are made of self-extinguishing materials, which ensures safety while transporting combustible items.

These belts are intended to withstand the corrosive effects of oil and grease. They are appropriate for transporting commodities containing petroleum products or for usage in settings with frequent oil exposure.

These belts are acid and alkali resistant, making them perfect for handling materials in harsh conditions such as chemical or metal mining activities.

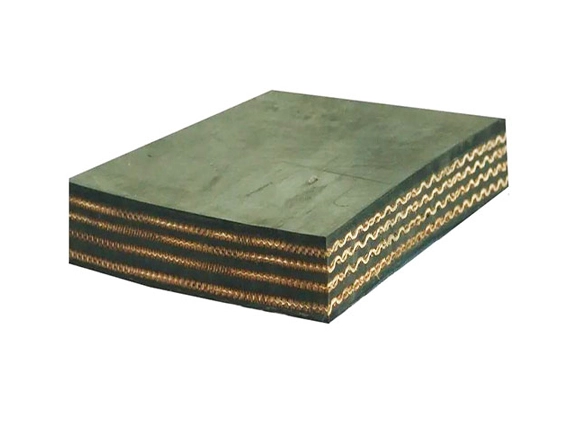

Solid woven belts are highly durable and wear resistant. They are widely employed in circumstances where heavy, abrasive materials must be carried over long distances. These belts are more widespread in Europe and Asia, but less typically worn in the United States.

Sidewall belts are constructed with vertical sidewalls to avoid material spillage, especially when conveying commodities on inclined conveyor systems. These belts help to increase efficiency in steep hauling operations.