Tel: +86-532-84673097

Mobile & Whatsapp & Wechat:+86-13589340409

Mobile & Whatsapp & Wechat:+86-13589340409

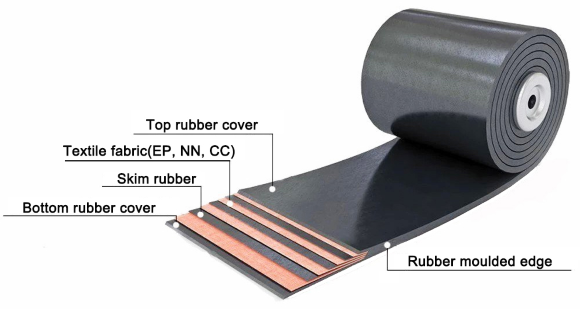

Carcass (Core Layer):

The core of a nylon conveyor belt is made from nylon fabric, which provides strength and flexibility. The carcass can be single-ply or multi-ply, depending on the strength required for the application.

Rubber Covers (Top and Bottom Layers):

Surrounding the nylon carcass, the belt is coated with rubber on both sides. The top cover is usually thicker to withstand wear and tear from materials, while the bottom cover is designed to provide grip and protect the carcass from friction against the conveyor rollers.

Bonding Layer:

In some cases, an additional adhesive or bonding layer is applied between the nylon fabric and the rubber to ensure strong adhesion between the two materials, enhancing durability and longevity.

Edge Protection:

The edges of a nylon conveyor belt are treated or sealed to prevent fraying and wear.

| Fabric Type | Fabric Specification | Fabric Layer Thickness (mm) | Single Fabric Strength (N/mm) | Covering Layer Thickness (mm) | Width (mm) | Length (m) | |

| Top Layer | Bottom Layer | ||||||

| Nylon/NN | NN-100 | 0.70 | 100 | 1.5-8 | 1-4.5 | 300-1800 | 20-300 |

| NN-125 | 0.75 | 125 | |||||

| NN-150 | 0.80 | 150 | |||||

| NN-200 | 0.90 | 200 | |||||

| NN-250 | 1.10 | 250 | |||||

| NN-300 | 1.25 | 300 | |||||

| NN-350 | 1.35 | 350 | |||||

| NN-400 | 1.70 | 400 | |||||

| NN-500 | 1.80 | 500 | |||||

| Adhesion and Elongation | |||||

| Belt | Adhesion | Elongation at break | |||

| Carcass | Interlayer N/mm | N/mm between rubber and carcass | Longitudinal elongation at break | Longitudinal reference elongation | |

| Rubber thickness ≤1.5mm | Rubber thickness >1.5mm | ||||

| Nylon Canvas | ≥4.50 | ≥3.2 | ≥3.5 | ≥10% | ≤4% |

| Cover Performance of NN Conveyor Belt | |||||

| Cover Level | Tensile strength | Elongation at break | Abrasion | Change rate of tensile strength and elongation at break after aging | |

| ≥ | ≥ | ≤ | |||

| Mpa | Kgf/cm² | % | mm³ | % | |

| Heavy | 24 | 240 | 450 | 120 | -25 ~ +25 |

| Medium | 18 | 180 | 400 | 100 | -25 ~ +25 |

| Light | 15 | 150 | 350 | 200 | -30 ~ +30 |

High tensile strength

Anti-impact and wear resistant

Exceptional corrosion resistance

Excellent flexibility and troughability

Good load bearing capacity

Light in weight

Strong adhesion

Mining and Quarrying: Transport bulk materials like coal, ores, and gravel with high tensile strength and abrasion resistance.

Agriculture: Convey grains and seeds, thanks to their lightweight, flexible, and moisture-resistant properties.

Manufacturing: Move raw materials or finished goods on assembly lines with flexibility and shock absorption for continuous operation.

Logistics and Warehousing: Manage material handling and sorting with long-lasting, high-strength belts.

Food Processing: Transport food products with moisture resistance and hygienic coatings for safe handling.

Power Plants: Support coal handling and ash transport with resistance to wear and tear.

Recycling & Waste Management: Transport recyclables like paper and metals with impact resistance and adaptability to heavy loads.

Textile Industry: Move fibers, fabrics, and finished textiles smoothly and efficiently.

Packaging Industry: Handle lightweight and heavy packaged goods with flexibility and strength.

Paper and Pulp Industry: Convey pulp and paper products with durability and moisture resistance for wet environments.

1. How do you select the right nylon conveyor belt for your application?

To select the right nylon conveyor belt, consider factors such as the type of material being transported, operating conditions (temperature, humidity), load weight, speed, and belt length. For high-impact or heavy-load applications, opt for belts with higher ply counts and abrasion-resistant covers. Additionally, consult with the belt manufacturer to customize a belt that meets the specific needs of your industry.

2. What are the key advantages of using nylon conveyor belts in industrial applications?

Nylon conveyor belts offer several advantages, such as high tensile strength, excellent elasticity, and superior resistance to abrasion, which makes them ideal for heavy-duty applications. They are lightweight, flexible, and have a high impact resistance, reducing wear and tear on machinery and improving energy efficiency. Nylon belts also have good adaptability to various working environments, including high humidity and temperature variations.