Tel: +86-532-84673097

Mobile & Whatsapp & Wechat:+86-13589340409

Mobile & Whatsapp & Wechat:+86-13589340409

Conveyor belts are crucial components in various industries, facilitating the efficient movement of materials. When operating in environments where oil exposure is a concern, selecting the right oil-resistant conveyor belt is paramount to ensure optimal performance and longevity. In this article, we will explore the factors to consider when choosing oil-resistant conveyor belts and provide some suggestions.

An oil-resistant conveyor belt is necessary due to the detrimental effects of oil penetration on conventional rubber belts. When oil infiltrates rubber, it induces swelling and distortion, leading to severe tracking and steering issues, premature wear, and eventual belt failure. These damaging effects stem from oils, fats, and greases, which can originate from two main sources: mineral and vegetable/animal. Therefore, employing the oil resistant conveyor belt in industries prone to oil contamination is essential to maintain operational efficiency, extend belt lifespan, and ensure reliable material handling processes.

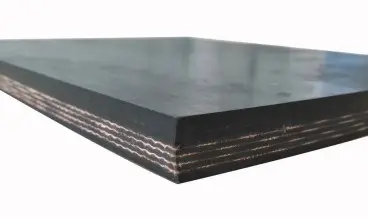

1. Prioritize Quality Materials: Opt for conveyor belts made from high-quality materials, such as NBR (Nitrile Butadiene Rubber) or SBR (Styrene Butadiene Rubber). These materials exhibit excellent resistance to oil, grease, and other petroleum-based substances. Look for rubber compounds specifically formulated to resist swelling, distortion, and degradation when exposed to oils. Furthermore, consider the type and arrangement of reinforcement materials in the belt, such as polyester, nylon or steel cord. These stiffeners increase the strength and durability of the belt, ensuring that it can withstand the harsh conditions of exposure to oil without premature failure.

2. Covering thickness and hardness: The thickness and hardness of the belt covering layer (hardness) is an important factor in its oil resistance. A thicker cover provides a more substantial barrier against oil infiltration, thereby enhancing the belt's resistance to degradation caused by oil exposure, while harder covering material exhibits greater resistance to wear and deformation caused by abrasive substances present in the oil, such as solid particles or contaminants.

3. Consider Temperature Range: Evaluate the temperature extremes within the application environment, taking into account both ambient and material temperatures. Consider factors such as hot machinery surfaces, steam, or extreme weather conditions. Choose a conveyor belt that can withstand these temperature fluctuations without compromising its structural integrity or oil resistance properties.

4. Testing and Certification: Ensure the conveyor meets industry oil resistance standards and certifications, such as ISO 340, ASTM D1460, or DIN 22102. Seek belts that have undergone rigorous testing to verify their performance in oil-bearing environments.

Rentone Belt is a professional oil resistant conveyor belt factory, offering oil resistant conveyor belts with upper and lower coverings with different oil resistance properties. Based on this, oil-resistant conveyor belts can be divided into anti-abrasive type (D) and general type (L). The specific working conditions for each type are as follows:

Anti-abrasive type (D): Type D has excellent oil and abrasion resistance properties, which are appropriate for conveying oily and greasy materials.

General type (L): Type L is suitable for conveying materials under normal working conditions.